Production

A century of textile innovation and experience dedicated to quality

From design to creation: an integrated process for custom solutions

For over a century, Lenzi Egisto has stood out for its ability to develop innovative textile solutions by combining artisanal expertise with cutting-edge technology.

Our integrated production structure allows us to manage every phase of the process in-house—from design to the final fabric—ensuring rigorous quality control and the flexibility needed to meet the specific needs of every client.

A concrete commitment to sustainability

We have equipped our facility with a state-of-the-art photovoltaic system that allows us to significantly reduce the environmental impact of our production activities and promote a sustainable and efficient industrial model.

This choice is guided by our vision of the world and our work, which is always oriented towards responsible innovation and respect for the environment and our local community.

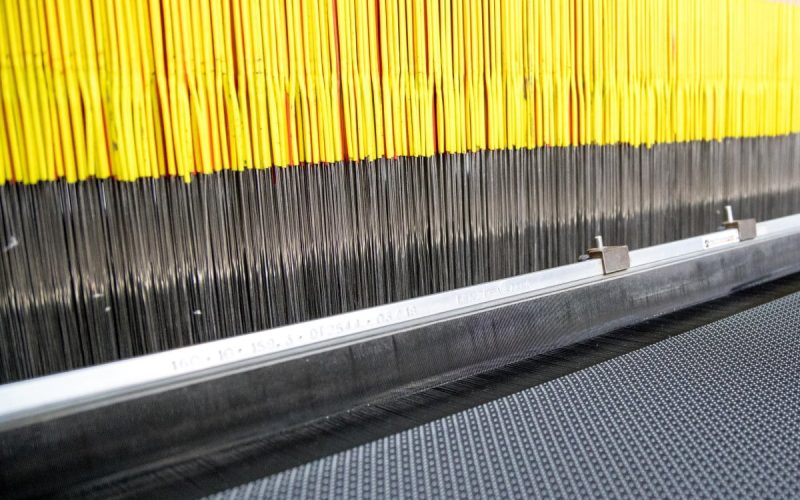

Dobby and jacquard weaving

We use heddles and jacquard looms to create complex, custom fabrics with technologically advanced fibers. This versatile approach allows us to create textile structures for various applications with high standards of quality and performance.

Lamination

The lamination process bonds different materials together to create composite fabrics with superior technical characteristics compared to traditional ones. This is a fundamental process to grant our products properties like waterproofing, mechanical resistance, and thermal comfort.

Printing

We offer advanced printing services to customize fabrics with company designs, logos, and patterns, using techniques that ensure long-lasting durability and high-level color rendering.

Quality control and packaging

Every product undergoes rigorous quality control checks to verify compliance with required standards. The fabrics are then carefully packaged to preserve their characteristics during transport and storage.

Sample development

We develop custom prototypes and collections, working in close contact with our clients to translate their needs into concrete textile solutions. This is an essential service for testing new ideas and adapting products to specific market demands.

In-House laboratory

Research and development for excellence

Our laboratory is equipped with state-of-the-art instruments to perform in-depth tests and analyses on our materials. Here is a glimpse on our equipment in use:

- Crockmeter and Multifiber DW for checking color fastness

- Chain protection testing machine

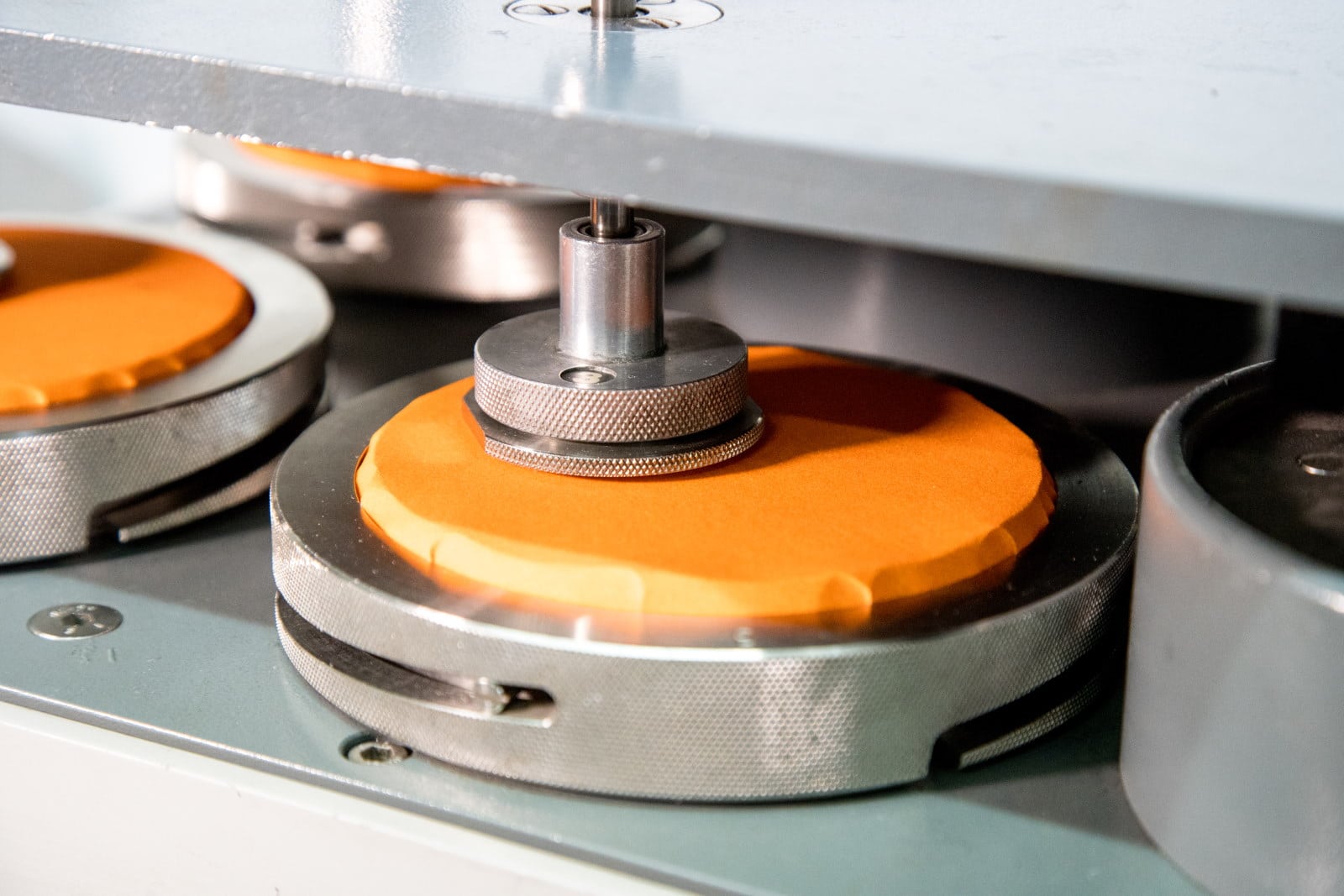

- Martindale for abrasion resistance

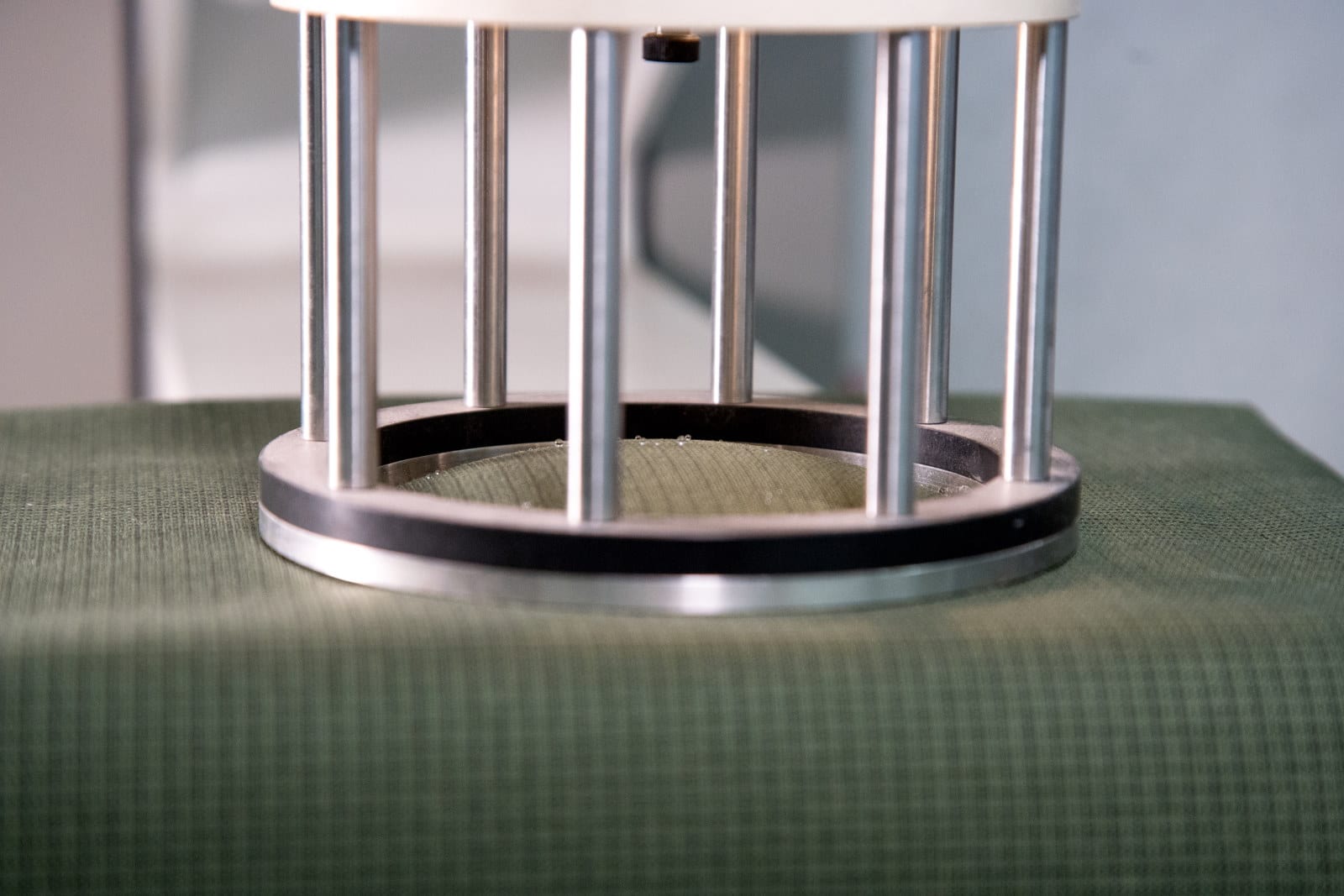

- Spray rating tester

- Bally flexing machine

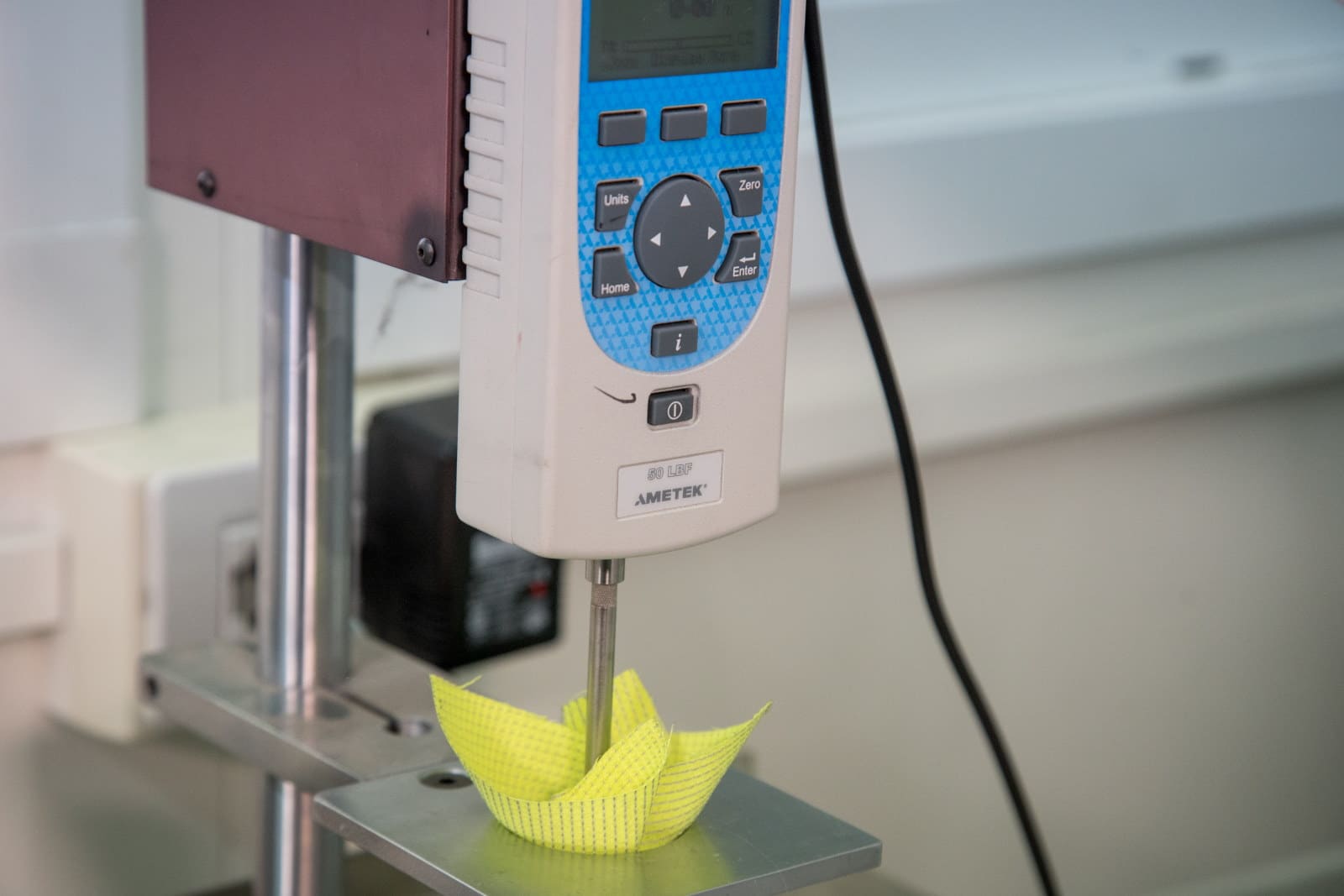

- Puncture resistance tester

- Electrical resistance tester

- Instruments for measuring thickness and weight

- Dynamometer for checking tensile, tear, adhesion, and thread tensile strength

- Stiffness tester

- Water absorption and desorption tester for insoles

- Penetration and absorption tester for safety footwear uppers

This equipment allows us to ensure that every fabric fully meets technical and regulatory requirements, guaranteeing reliable and long-lasting performance.