A ‘coagulated’ textile material without resins, which remains clean when cut and is resistant and compact during skiving.

Lenzi Egisto is sustainable from start to finish. In the sense that the Tuscan company was born with recycling and even today, after more than a century, its research and development activities have led it to bring to market a new environmentally friendly material in demand in the manufacturing world. But let’s proceed in order and start from the beginning, precisely.

In Prato, in 1898, Egisto Lenzi began his business recovering noble fibres from discarded clothing. An activity that nowadays we would call “virtuous fiber recycling”.

After a few years of selling recycled fibers on the local market, the company began producing its own fabrics and established its first production unit. Developments were rapid and, in 1936, it became necessary to increase production by adding the Vaiano production site, with a larger industrial area, where the headquarters and part of the Lenzi Egisto production are still located today. The production of “unconventional” fabrics and the continuous search for innovative textile solutions began immediately after the war.

Over the last thirty years, however, major technological transformations in the textile sector have enabled the consolidation of new commercial strategies and the search for innovative textile solutions in the military clothing, protective textiles, and functional fashion sectors. Sometimes “visionary” solutions, but which have confirmed Lenzi Egisto as a brand synonymous with quality textile innovation. Lenzi’s research and development has always been aimed at offering new materials, developed to meet specific and concrete market needs.

As happened in the mid-90s when Jacquard fabrics made with high-tech fibers were introduced, even among the major fashion brands, which guaranteed resistance and functionality even to fashion accessories while maintaining an extremely ‘glamorous’ look and feel.

In the early 2000s, Lenzi launched barrier fabrics for anti-perforation insoles of safety footwear, capable of replacing uncomfortable and heavy steel midsoles. Since then, the world of safety footwear has never been the same.

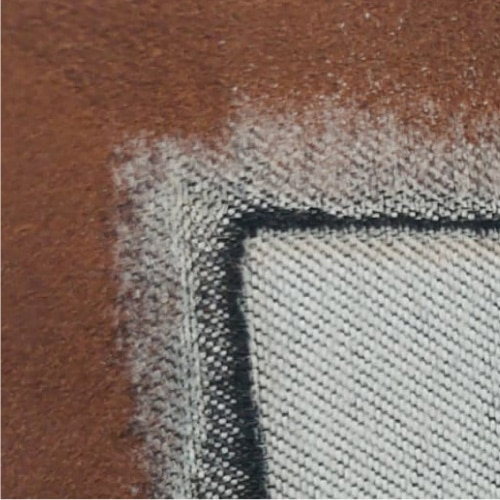

It was said that Lenzi Egisto is a sustainable company from start to finish. We come, then, if not to the end, to current events. Today LENZI has responded to the market’s demand for a solution to the problem of leather underlayment reinforcements. Traditional microfiber reinforcements, produced with “aggressive” chemical processes, are no longer acceptable. “To offer a sustainable, environmentally friendly, and zero-mile solution, we needed to be able to produce an alternative product in-house: a resin-free, ‘coagulated’ textile material that would remain clean when cut, durable, and compact during skiving,” they explain at Lenzi Egisto. This is how MICRO LENZI was born, the new textile reinforcement resulting from research conducted on innovative fibers that manage to remain cohesive without the need for resins of any kind. Polyamide-based fibres produced in Europe.

MICRO LENZI materials are entirely woven and finished in the Vaiano factories, near Prato, Tuscany.

Micro Lenzi products, although resin-free and sustainable, are easy to use. They are suitable for gluing onto leather, can be trimmed without any problem, and can be stripped to leave a clean, fray-free edge, even when raw cut.

It is available in three colours (White, Grey and Black) and in five weights, to cover the various reinforcement needs of the various types of leather.